Custom gas spring solution for the maintenance flap of a ground coffee compactor

The maintenance flap places high demands on the gas spring function

A life without a cup of coffee is hardly imaginable for most of us. Coffee, water, coffee machine on and shortly afterwards the coffee is ready. Behind this, however, there are highly complex manufacturing processes and machines. One of them is the ‘ground coffee compressor’. Freshly ground coffee has a relatively large volume and must therefore be compacted before packaging.

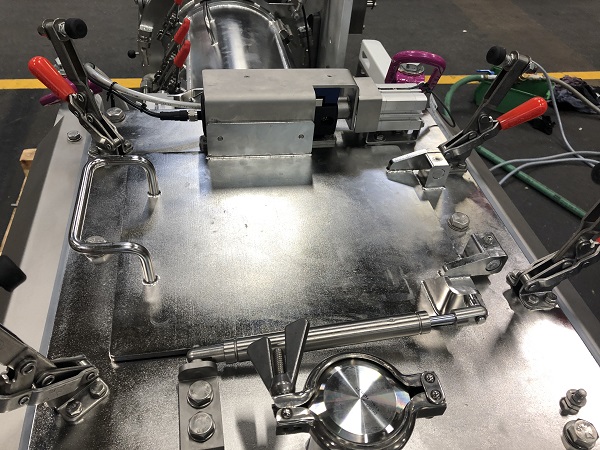

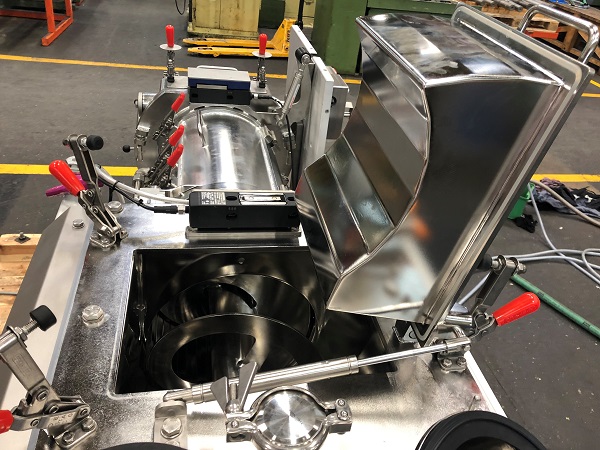

Just as many other machines, the ground coffee compressor also has a maintenance flap.

The following requirements were placed on the operation of the flap:

- It must remain in closed even after the locking device has been released.

- It should be very easy to open.

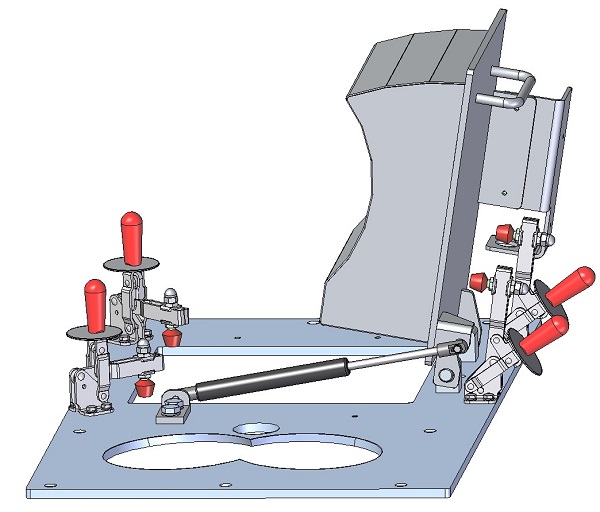

- It must stay reliably open at an angle of approx. 100°.

- When closing, the gas spring must hold the flap until shortly before the closed position.

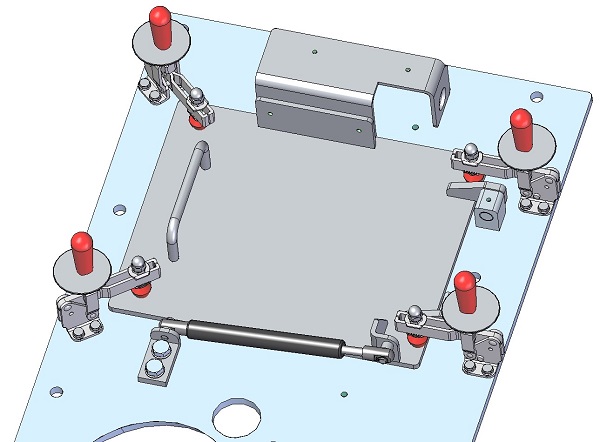

Implementing these requirements became more difficult due to the fact that the gas spring could only be installed on top of the flap (outside the compressor) and the pivoting point was far outside the flap. Thus, it was necessary to calculate the mounting position with absolute accuracy and to design the gas spring accordingly. Even a 5 mm displacement of the installation points would have led to malfunction. The technical know-how of the DICTATOR employee was put to test!

Other aspects to consider when determining the type of gas spring:

- Direct use in food processing: Hence the AISI 304 version and the use of bio-oil with H1 approval. Each gas spring contains a small amount of oil to lubricate the seal and to achieve damping, in this case, when the piston rod extends, i.e. when the flap is opened.

- Since the gas spring cannot be installed with the piston rod pointing downwards (important for lubricating the seal at the front of the cylinder), it had to be equipped with an oil chamber so that the seal never runs dry.

The gas spring enables easy operation of the maintenance flap despite the difficult installation situation

DICTATOR provided the customer with an exact calculation of the gas spring and its installation position. Since the customer had used a 3D program to design the flap, DICTATOR also provided him with a STEP file of the calculated gas spring, which he could then integrate directly into his design. This allowed the perfect function to be tested in advance on the 3D model.

As for many other areas, the gas spring for such ground coffee compressors are manufactured – in addition to the standard models – for customer-specific projects, even as single units. That’s why DICTATOR was the ideal partner for the company Bauermeister. Even if only one gas spring is required, as in this case, it was a given for DICTATOR to support the customer from the enquiry to the successful completion of the project – and, of course, to manufacture the gas spring as a single unit with the exact required specifications – despite the high effort needed for its calculation.

The perfect interaction between the gas spring and maintenance flap was already verified in the 3D simulation. For the customer, it was a time-saving and valuable support that DICTATOR provided the gas spring exactly in the required dimensions and with the intended fixings as a STEP file.

Products used

Push-type gas springs

The application possibilities of DICTATOR gas springs are as varied as our model variants. That is why DICTATOR does not have fixed type tables and only a few stock types. We manufacture our gas spring for your application according to your wishes – from a single unit to large quantities. In addition to high quality, DICTATOR gas springs also offer numerous possible additional features such as a valve, oil chamber, protective tube, compression spring or bio-oil, which considerably extends the range of possible applications.