DICTATOR Española

History | About us | Our strengths | Quality | Products

History

DICTATOR Española was founded on October 1st, 1973 in Barcelona, initially as a mere DICTATOR sales subsidiary. At the beginning, the focus was on the sale of DICTATOR elevator door dampers, as the elevator sector in Spain was already vast at that time, compared to all other European countries.

Over the years, DICTATOR Española’s activities in the elevator sector continued to expand. Additional products were marketed, such as elevator doors, and engineering services for complete installations were also taken on.

In 1989, DICTATOR Española then moved from rented office space in the city to its first own facility in Barberá del Vallés, northwest of Barcelona.

25 years after its foundation and only 9 years after the move, even these premises were too small. In 1998, a completely new hall, tailored to the needs of DICTATOR Española, was opened in the newly developed Polígono Industrial Can Salvatella of Barberá del Vallés. This step had become necessary because, by now, complete homelifts were also being sold and the company’s activities had expanded more and more into the area of door and gate operators. In 1998, the automation of a 61 m wide sliding fire door was completed in cooperation with the other DICTATOR companies, followed by other large-scale installations in 1999, including a door with a 93 m opening width.

In 2002, DICTATOR Española began manufacturing their own shaft systems for elevators in their own factory. Production was expanded to include the DICTATOR Homelift DHM and now also includes the DHE lift.

DICTATOR Española today

About us

For more than 40 years now, we have been an integral part of the DICTATOR Group – and this has not remained without consequences: bit by bit, we have made the quality standards of our German colleagues our own, we are big fans of homemade German cake, which is now an indispensable part of the luggage for every visit from Germany – and of German Christmas cookies. In return, we were able to impress our colleagues from the other DICTATOR companies with our services – AND get them excited about Spanish culture, a “win-win” situation for everyone!

The last economic crisis, which hit Spain particularly hard, also had a positive effect on us: we at DICTATOR Española came even closer together, as we all stuck together uncompromisingly and thus overcame this crisis as a team through the personal commitment of each individual. Thanks in no small part to our resourcefulness, because we also strive to meet customer requests that at first seem almost impossible to realize, and ultimately find a solution for them – because we love a good challenge!

Our strengths

DICTATOR Española was initially established as a mere sales subsidiary. At that time, it was neither planned nor foreseeable that we would one day become an important DICTATOR production site. However, the Spanish market made increasingly high demands on products and solutions in the elevator sector. And we rose to the challenge. An in-house design division in the elevator sector was the result. It was then only a matter of time before our own production came into being. The big advantage was that the products could be tailored precisely to market requirements, to the market segment served by DICTATOR Española – namely high-quality systems that could flexibly adapt to exceptional space conditions in existing buildings. As with all other DICTATOR operations, special solutions are our everyday business. And since we also assemble some of our systems ourselves in Spain, we have an additional quality control system that allows us to put our products to the test once again.

From the elevator sector, it was only a short leap to the door and gate operator segment. Here, too, the focus is on the special requirements of our customers. The expertise of our design department and the know-how of our engineers are the key to our success. This quickly led to special projects, which at the beginning were unprecedented in the DICTATOR Group, but which could also only be solved through the intensive and close cooperation with the other DICTATOR companies. In this context, we benefited and still benefit from the day-to-day dealing with complex requirements from the elevator sector, which can only be met by a very structured approach. The wealth of experience we have accumulated over the years also makes it possible time and again to find special solutions that can only be realized by combining products from the elevator and drive sectors, as was the case, for example, with the automation of a 14-meter high lift gate. Here, hydraulic cylinders were used that are normally used in our elevator systems.

Our team of 17 employees has learned to make a lot out of a little. The most important prerequisite for our success is our willingness to deal with all requirements and problems, to never give up and to develop solutions with a wealth of ideas that would have been impossible for others.

In this way, we have built up a reputation over the past decades as a reliable, competent partner, which has been extremely helpful to us during times of economic crisis that hit Spain particularly hard.

On the production side, the special challenge for us is that all DICTATOR liftsand shaft systems are always manufactured on a customer-specific basis. Each elevator, each shaft system is an individual production. In order to be successful here, we had to organize all processes tightly and effectively in order to be able to produce on time and without errors. Various, self-developed, individual adaptations of standard programs to our special needs save an enormous amount of time, and sources of error have been successfully eliminated.

Since 2015, DICTATOR Española has had a state-of-the-art laser cutting machine with automatic loading and unloading station, which enables us to make production even more cost-effective and efficient and, above all, to consolidate our high quality standards – despite demanding, order-based production.

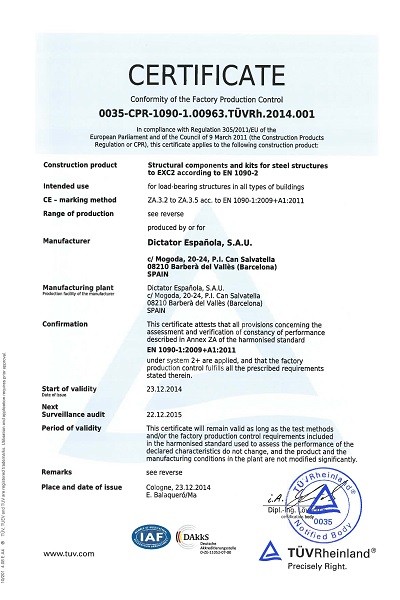

Quality

Quality is an essential part of our everyday business at DICTATOR Española:

- In the development of our products, because our DHM homelift and DHE lift are type-tested. We were the first Spanish company in this field to receive EN 1090 certification for our shaft system. In the design process, we also place the highest value on ensuring that all our products are extremely robust and solid, as this is the only way to achieve long-term problem-free, reliable operation and guarantee that the user can rely on their elevator.

- In manufacturing, because our DHM homelifts, DHE lifts and shaft systems must meet the strictest safety requirements. Our goal is to contribute to accessibility with our products and to make life easier for the users. This is why, for example, all elevator cars produced by us are first assembled in the factory to ensure stability as well as a perfect fit of the car and chassis, including all relevant safety components.

- When selecting our suppliers, because they must share our quality policy. We also only use components that have been tried and tested internationally.

- In the organization of our processes, because this is the only way we can ensure that we work efficiently and that only flawless products leave our production facilities.

- In advising our customers, because we want to provide them with solutions to their problems with which they are completely satisfied.

Products

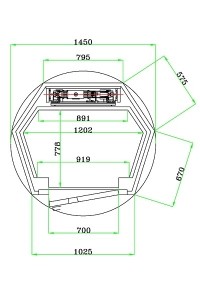

All custom-made and suitable for almost every requirement