DICTATOR Productie

History | About us | Our strength | Quality | Products

History

DICTATOR Productie was founded by the Trapman family on June 6th, 1932, shortly after the DICTATOR door damper had been patented. At that time the company name was still NV DICTATOR deursluiter maatschappij. The company was initially located in Amsterdam, and then in Bussum, near Amsterdam.

The production of the DICTATOR door damper started in a garage. Step by step it grew and in 1965 it was moved to Emmeloord, in the Noordoostpolder. The Noordoostpolder was reclaimed from the Ijsselmeer in the 1940s and lies about 5 m below sea level. An ideal place for an ambitious company!

DICTATOR Productie later joined the DICTATOR Group in 1988. Until then, DICTATOR Productie and the German DICTATOR Group had been competitors! Both company branches had developed independently of each other, both had the patent of the DICTATOR door damper as a basis, which had been co-invented by a German and a Dutchman.

In the mid-80s it became clear that there were no successors within the Trapman family, the owners, who wished for the company to carry on. And so the German and Dutch “descendants” of the original inventors of the DICTATOR door damper turned from competing against each other into working together once again.

As a result of reunification of both companies, sales of DICTATOR door dampers (for hinged lift doors and for all other types of door) rose sharply thanks to joint efforts and led to extensive expansion of production. In 1996, a spacious assembly hall was built. Due to the sandy subsoil – the company stands “op de zeebodem” (on the seafloor) after all – , the hall had to be built on concrete pillars over 9 m long.

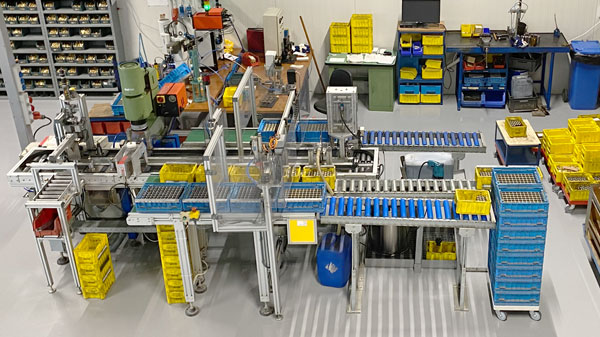

In 2003, a new, modern machine hall was added to replace the previous old hall. This created ideal conditions for the state-of-the-art machinery as well as the fully automated cylinder production, visible evidence of the DICTATOR success story that began in 1932 with a joint invention and is now being continued together.

DICTATOR Productie today

About us

Pioneer spirit lay the foundation of our company – because without it, the DICTATOR door damper would never have come into being. And it has remained a determining factor in our success story since 1932. It was just as necessary when settling in the Noordoostpolder, an area 5 meters below sea level, as it was when conquering new markets, since the Netherlands itself was too small a sales market in the long run.

However, a fundamental premise for pioneering spirit is also the cohesion within our company, the collaboration with each other and the appreciation of each and every employee.

Our strengths

From the very beginning, DICTATOR Productie has always considered production to be inseparable from sales. This is also a reason for the outstanding quality as well as the large variety of DICTATOR door dampers. This is because they have constantly improved in response to the demands of the market, and new models have been created.

The many – mostly unsuccessful – attempts to copy our door dampers have also spurred us on to constantly improve and automate our production methods, so that we can produce extremely cost-effectively despite our location.

The challenge for us lay in developing machines and production processes that are flexible enough to cope with our enormously high variety of models. Regardless of this, all steps that can be performed faster and with higher quality by machines than by humans are automated as far as possible.

We constantly face this challenge again and again. Know-how gained from over 90 years of experience in production, openness to new ideas, a willingness to put the status quo to the test over and over again, and the enthusiasm of our employees to constantly work on further improvements – all this has led to our always being at the forefront of production technology. Our first robot, affectionately known as “Robby”, went into operation as early as the 1980s.

In the meantime, “Robby II” has taken its place and performs its service diligently and without failure. Intelligent automation (which also includes the CAD/CAM control of our CNC machines) has created even more flexibility than before, with correspondingly high quality and short lead times.

In addition to the door dampers that marked the beginning of our success story, many other products have been added over the years – always in response to the demands of the market. A very good example of this is our “mechanical timer”, which ensures that sliding doors only close after an preset time, completely without electricity. A product that is based on the functional principle of our door dampers, but meets completely different requirements.

Our swing door hinges have also become indispensable on the market. Due to their special function and high quality, they are far superior to standard swing door hinges. Other products include the door holder ZE and our closing springs, such as the Piccolo or the built-in Adjunkts.

Quality

There are many attempts to copy the products manufactured at DICTATOR Productie. However, the quality of our DICTATOR products is unmatched. DICTATOR Productie – like the other DICTATOR production sites – has succeeded in mastering the gap between highest quality, flexibility as well as cost-effective production due to the know-how built up over decades, paired with personal commitment as well as the unrestrained enthusiasm for new things. The cylinders of our door dampers are made of solid material – the only way to achieve our superior DICTATOR quality.

DICTATOR Productie’s equipment includes several sliding lathes, an automatic lathe for the door damper cylinders with a robot extraction and inspection station, an OKUMA lathe center, which enables the extremely small tolerances of the piston sizes required for the perfect functioning of DICTATOR door dampers, and a fully automatic system for assembling the cylinders – of course with built-in quality control there as well. After the final inspection, each cylinder is engraved with a code that provides information about the exact type and the production batch. This ensures complete traceability of every DICTATOR door damper.

There are also conventional machines available to ensure the necessary flexibility, the development of new products and the necessary production of prototypes as well as special models.

All products are constantly subjected to stress and endurance tests in our in-house testing facility, because sturdiness and durability are important quality features of all DICTATOR products.

Products

The complete production program of DICTATOR Productie at a glance:

- DICTATOR door dampers (VS 2000, V 1600, R 1400, H 1300, Z 1000, Z 1100, Junior)

- DICTATOR standard lift door dampers (Standard Germany, Española, Schindler, F, Fortis, Boetticher, Haushahn, Medasa, Ceita…., more than 30 models in total)

- Closing springs

- HAWGOOD swing door hinges

- Door holder ZE

- Release buffer for sliding doors

- Mechancal timer

- Thermal bolt HLS-Catch for fire doors

- … and many more custom solutions