WaCo GERÄTETECHNIK GmbH

History | About us | Our strenghts | Quality & environmental protection | Products

History

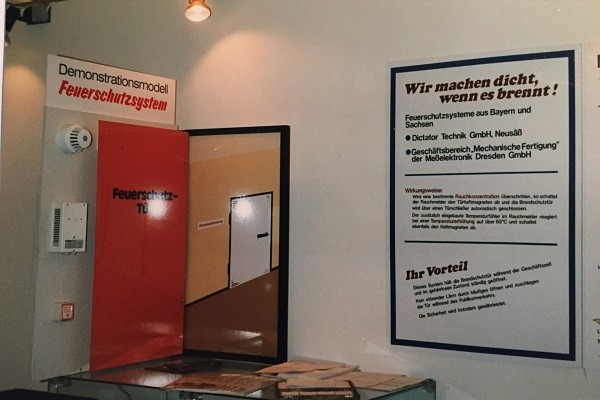

The cooperation between DICTATOR Technik GmbH and WaCo GERÄTETECHNIK GmbH started in 1991, one year before the foundation of WaCo. DICTATOR was looking for a reliable partner for the production of their own electromagnets. This search led to the company Meßelektronik, or more precisely, to its “Mechanical Production” division. An engineer, enthusiastic about the new challenge, quickly turned DICTATOR’s inquiry as to whether they could manufacture electromagnets and presented the first fully finished electromagnet during a surprise visit to Neusäß. This laid the foundation for a close cooperation.

In 1992, the company WaCo GERÄTETECHNIK GmbH was created from the mechanical manufacturing division of Meßelektronik through a management buy-out, with DICTATOR as one of the shareholders.

Despite difficult initial conditions, the two Dresden-based partners and managing directors Volker Wahl and Uwe Paulick succeeded in turning this company into a model business within a few years.

Initially, WaCo had to continue working in the run-down building that housed the mechanical production. An important part of the company’s equipment were buckets, because the roof wasn’t leak-proof anymore! But by the end of 1996 WaCo had made it: the company moved to Weixdorf in the north of Dresden – into its own, newly built, modern building with 1500 sqm production area. At the inauguration ceremony on April 4, 1997, the 5th anniversary could be celebrated at the same time. Not even 5 years later, another hall was added and put into operation in October 2000.

In the 2nd quarter of 2010, the punching and laser machines then moved to a completely new building in the same industrial area. A high-bay warehouse was built there, which fully automatically supplies the machines with material and also transports it away again. A second assembly hall and a spacious office building followed. The previous halls are used for storage purposes and the final assembly of complex, large control cabinets.

Since 2019 WaCo is a part of the Wickeder Group.

The focus of the cooperation between DICTATOR and WaCo is particularly in the area of electromagnets as well as door interlock systems. However, WaCo’s actual core business has been “services in sheet metal” since the company was founded.

In the beginning, WaCo specialized more and more in complete sheet metal products and also took on design work for customers as a problem solver.

The fact that this was exactly the right way was shown not least by the state-of-the-art machinery for sheet metal processing, which grew from year to year. In 1992, the year the company was founded, the first Trumpf CNC rotary punching and nibbling machine, the Trumatic 120, was installed.

This was followed by other state-of-the-art Trumpf sheet metal processing machines, from the Trumatic 500 to the combined punching and laser cutting machines TC 600, TC 6000 and TC 7000, but WaCo’s machinery also includes many other CNC sheet metal processing and cutting machines.

WaCo today

About us

In the less than 25 years of our existence, we have managed to increase our workforce from 27 employees in 1992 to almost 80 now, plus an additional 7 trainees. It was always important to us to keep the company “lean”, not to build up useless hierarchies and to always work with the latest technology. And we were always looking for new challenges. That’s why we quickly evolved from a pure contract manufacturer in the sheet metal sector to a provider of all-in-one packages. We design for our customers, optimize their equipment for them and manufacture it on state-of-the-art equipment. We are proud to count such renowned companies as Siemens, Bosch, Dräger and many more among our customers – and of course DICTATOR as well.

All our employees pull together and so we believe that those who work hard should also party hard. Every 5 years there is a big celebration on the agenda, whether in our offices, on a trip on the Elbe or in a brewery.

Our strengths

A certain pioneering spirit was already part of the foundation of WaCo, the willingness to take a considerable risk. And this attitude has never left us. Our goal has always been to provide our customers with the best possible services and products, always taking advantage of the latest technology. Through the targeted use of new technologies, we have been able to constantly expand our program and offer competitive prices at the highest quality.

Currently, the latest innovation at our site is our Trumpf laser welding robot, which enables us to weld housings so precisely that no weld seams are visible and no subsequent grinding is necessary. Distortion is much lower and the pure welding time is extremely short.

A prerequisite for this, however, is a design that is completely suitable for laser welding, something that our designers also had to learn first. In addition, our work preparation department now has to design fixtures that were not previously required for conventional TIG welding.

Always getting involved in new things, always wanting to be ahead of the game, that is one of our very decisive strengths.

Quality

All operations and processes of our company are integrated in our quality management system according to DIN ISO 9001:2008.

Customer audits, which have been carried out many times and successfully passed, are proof of our high quality level.

Quality at WaCo Gerätetechnik GmbH consists of many elements:

- friendly and reliable contact with the customer

- on-time deliveries

- high-quality and dimensionally accurate parts and assemblies

- fair dealings with partners and employees

- environmental protection

Environmental protection

As a medium-sized Saxon company, we are aware of our responsibility towards the environment and are committed to the economical use of raw materials and energy:

- Efficient use and correct selection of the products and processes used begin with the design and procurement of materials.

- The use of modern and regularly maintained machines as well as qualified personnel contributes to the avoidance of malfunctions and accidents.

- All regulations concerning storage, handling and disposal of auxiliary and operating materials are known in the company and are observed.

- We pay attention to the best possible separation and recycling of accumulating recyclable materials.

- All employees are called upon to continuously improve environmental protection and to use resources sparingly.

Our products meet all specified legal requirements and guidelines.

The implementation of and compliance with RoHS and REACH have been tested in our company for all delivered products.

Products

DICTATOR Products

- Electromagnets with counter plates (amongst other tested according to EN 1155)

- Interlock control system with power packs, centrals, terminals and other related components. If required, also with ATEX or UL authorization

- Casings for different DICTATOR power packs and control systems

Services in sheet steel and more

- Engineering

- CNC sheet steel technologies

- Mechanical working

- Welding technology

- CNC cutting

- Assembling

- Surface engineering