HLS thermal bolt

Safely closed fire doors – without gap

Characteristics

Perfectly functioning fire and smoke doors are an indispensable requirement for preventing or limiting damage. In the case of hinged doors in particular, the high heat of a fire might cause the door to warp, which can create gaps and thus the fire could spread despite the fire door. The Hot-Locking-Safe thermal bolting offers protection for these cases.

Available in two different models, which differ only in their counter plate.

IMPORTANT: The HLS thermal bolt may only be installed in agreement with the respective door manufacturer.

Product details

Technical data

| Casing | zinc-plated steel |

| Material soldered strut | Hotmelt |

| Melting point | at a surrounding temperature of about 600 °C, the soldered strut itself at about 65 °C |

| Spring force | approx. 11 N |

| Stroke | 23 mm |

| Application area | hinged fire protection doors T30 and T60 |

| Door types | timber and steel doors with timber or steel frames |

| Test | DIN EN 1634-1:2000 |

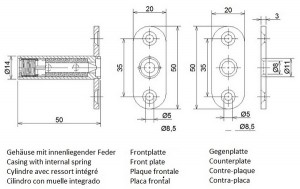

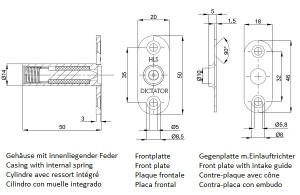

Models

- Standard model: the counter plate features just a countersunk bore as intake for the bolting pin

- Model for doors that warp more easily: here the bore in the counter plate is moulded as a funnel to enable the locking pin to enter the boring in the counter plate easierly, even when the door has already deformed a little.

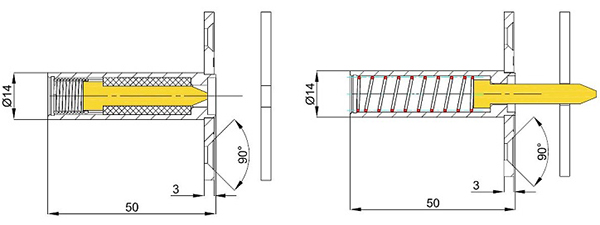

Function

During a fire it can happen that large door leaves – even if safely closed at first – are pushed open in some places due to high temperatures and the subsequent pressure difference. Through the gap that has been created, the fire may still spread despite the fire door. The HLS thermal bolt has an integrated pin that is released when a certain temperature is reached. The heat melts the plastic surrounding the pin and releases it, locking it into the door and thus preventing it from warping, which also prevents the formation of gaps that can let the fire spread despite the fire door.

Mode of operation

- Installed in the frame or the door at those places where there is the highest danger that a gap might occur.

- Normally the bolt is retracted in the casing and locked there by the soldered strut.

- Only when the surrounding temperature rises to about 600 °C and the HLS itself has reached about 65 °C, the soldered strut melts and the spring in the back of the cylinder can push out the bolt.

- This fixes the door securely to the frame and the door leaf cannot be distorted.

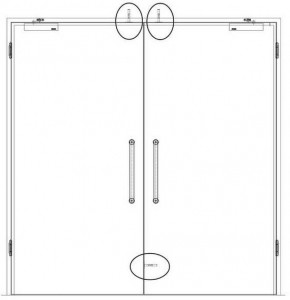

Installation

Installation notes

Usually the HLS thermal bolting is installed in the frame. However, it is also possible to fit it into the door leaf. The number and position have to be decided upon together with the door manufacturer.

Usually the HLS thermal bolting is installed in the frame. However, it is also possible to fit it into the door leaf. The number and position have to be decided upon together with the door manufacturer.

It is very important that both HLS thermal bolting and its counter plate are mounted exactly opposite each other.

Installation instructions

Order information

Order Information

| Description | Part No. |

|---|---|

| Thermal bolting TV2003-50, granulate material, bolt 23 mm stroke, counterplate with intake guide | 710717 |

| Thermal bolting TV2003-50, granulate material, bolt 23 mm stroke | 710715 |

Downloads

| File Name | Type | Date of modification |

|---|---|---|

| Catalog: Accessories for fire doors | 2022/05/18 | |

| Installation Instructions | 2022/05/18 | |

| 3DPDF Thermal bolting, 710715 | 2018/01/10 | |

| DWG Thermal bolting, 710715 | dwg | 2018/01/30 |

| DWG Thermal bolting, 710717 | dwg | 2018/06/22 |

| STEP Thermal bolting, 710715 | STEP | 2018/01/10 |