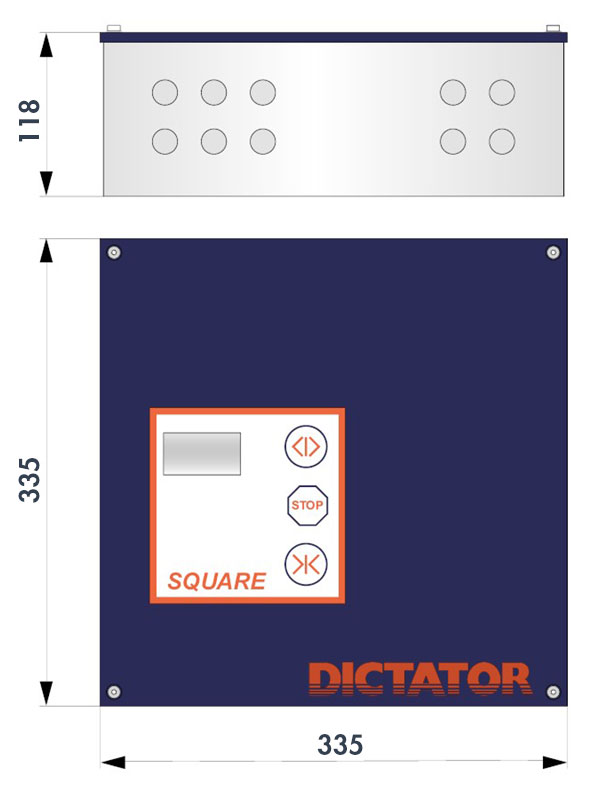

Control system SQUARE 940-2

with frequency converter according to EN 12453

Characteristics

- can meet the requirements of EN 12453 for the safety of use of power-operated doors

- For sliding or hinged door operators with three-phase motor up to 0.75 kW

- Suitable motors: 230/400 VAC (3-phase), max. 0.75 kW

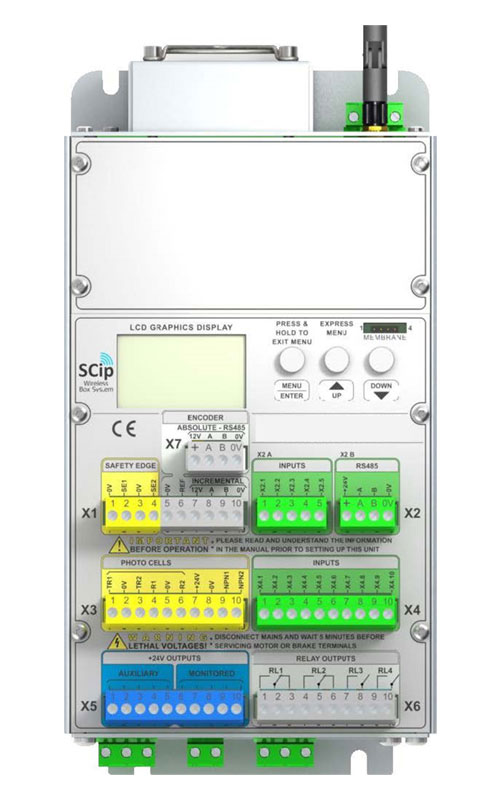

- Position detection: Encoder or separate limit switches

- Integrated frequency converter

- Dead man, pulse or automatic operation selectable

- Emergency operation in case of broken safety device

- Programming and setting are carried out via the programming keys on the control box

- 5 freely programmable relay contacts

- Password protection for safety-related settings

Product details

Technical data

| Rated input voltage | 24 VDC | 230 VAC / 50/60 Hz |

|---|---|---|

| Consumption | 3 A | 0,5 A |

| Motor rating | 120 W | 120 W |

| Torque | 25 Nm | 25 Nm |

| Power supply for additional components | 24 VDC / max. 0,3 A | 24 VDC / max. 0,3 A |

| Opening time | min. 3 s/90°, max. 6 s/90° (adjustable) | |

| Closing time | min. 3 s/90°, max. 6 s/90° (adjustable) | |

| Hold-open time with closing delay | 0 - 30 s (adjustable) | |

| Hold-open time with closing delay | - with 900 mm door width max. 100 kg - with 1000 mm door width max. 80 kg (see diagram below) |

|

| Opening angle | max. 100° | |

| Duty cycle | 80 % | 80 % |

| IP rating | IP 30 | IP 30 |

| Operating temperature range | -10 °C to max. +50 °C | |

| Position control | encoder, teach-in via automatic teach-in run | |

Operating functions / safety features

- Dead man or impulse function for the OPEN and CLOSE buttons (can be selected separately for each direction, e.g. impulse OPEN, dead man CLOSE)

- Automatic closing: The gate closes automatically after a time that can be set in the control unit (1 to 999 sec.) after reaching the OPEN position

- Alternating impulse OPEN/CLOSE or alternating impulse OPEN/CLOSE combined with automatic closing

- Partial opening: The door only opens partially (additional adjustable OPEN position for pedestrian opening) (separately adjustable automatic closing with hold-open time specially adjustable for this position)

- STOP (normal stop in direction OPEN, quick stop in direction CLOSE)

- EMERGENCY STOP: Functions like the safety device to secure the closing edge – stopping distance according to EN 12453

- Safety equipment:In accordance with the requirements of EN 12453, there are connection options for the safety equipment with different functions or safety categories. In the final positions, the safety equipment is deactivated. After response, a new run command is always required.

Securing of the main closing edge (direction CLOSE): Upon triggering, the door stops within the prescribed distance (like emergency stop) and reverses back to the open position. The safety equipment is only active in the CLOSE direction.

Securing the door edge in the OPEN direction (separate connection): Upon triggering, the door returns to the closed position. The safety equipment is only active in the OPEN direction.

If the safety device is damaged, emergency operation (dead man) can be selected. The door then only moves at creep speed. As long as the emergency mode is not set, the door can no longer be moved by the motor.

Functions

- Position control: The SQUARE 940-2 control system is designed for a position control via encoder, integrated

in the door operator. This permits a very precise positioning of the door (depending on the travel and the power transmission: max. 2 mm). However it is also possible to use separate limit switches (4 pcs. required). - Relay contacts: The SQUARE 940-2 disposes of 5 relay contacts for controling signalling and warning devices. There exists a large variety of adjusting possibilities. This permits e.g. the connection of signals, warning sirens, the connection to a building surveying central, a floor conveyor system etc.

- Diagnostics: The display on the lid of the casing indicates error codes or different diagnostic codes for the input and output terminals. This helps also to locate a problem, even by telephone.

Motor parameters

In order to achieve an optimum adjustment of the door drive to the door different motor parameters can be adjusted. Amongst them are e.g.:

- Motor Rating (adaption to the connected motor)

- OPENING Speed / CLOSING Speed (separately adjustable)

- Creep Speed before reaching the positions OPEN and CLOSED (speed is reduced before reaching the final position, so that no separate final dampers are required, separately adjustable)

- Acceleration and Deceleration Ramps: Depending on the door weight and its easy movement

- Fast Stop: Adjustment of the Stop in closing and opening direction (separately adjustable)

- EMERGENCY STOP: Adjustment of the STOP characteristics upon activation of the safety equipment or by the Emergency Stop push button

Installation

Installation notes

- The installation of the control system is very easy, as the electronics are fixed on a board that can be removed completely from the casing. The lid of the casing can also be taken off, as the flat cable connection to the display in the lid just has to be unplugged.

- The now very light casing can be fixed to the wall, without the danger of damaging the electronics by chance with e.g. a screw driver.

- The control system should be placed not farther than 30 m from the door operator. Door operator, operating elements and safety equipments are connected to the removable binders.

- The blocks of binders are coded and therefore cannot be plugged into a wrong position.

Order information

Order Information

| Description | Part No. |

|---|---|

| SQUARE 940-2 control system | 706094-2 |

Downloads

| File Name | Type |

|---|---|

| Documents | |

| Catalog: SQUARE 940-2 Control System | |

| Technical Manual SQUARE 940-2 |