Universal control unit Multi Control

Control unit for universal use with remote access

Characteristics

- Control unit with remote access: programming, diagnosis

- Logbook for tracing possible error states

- Configuration and settings can be accessed either via the display of the control unit or via smartphone, tablet or notebook

- For sliding / hinged / lift gates and doors

- Connectable motors: up to 200 W / 24 V DC

- Position recognition: encoder, position sensors, limit switches

- Built-in load cut-off for DC operators

- 16 free programmable (subsequently changeable) inputs and outputs

- Password protection for security-relevant settings

- Emergency power operation via battery pack possible

- Replacement for some old control units that are no longer available

- Different “Stops” of the door adjustable

Product details

Technical data

| Voltage | 90 – 264 VAC or 127-370 VDC |

| Power consumption | 2 A / 230 VAC |

| Output voltage (secondary) | 24 VDC |

| Output voltage motor | 24 VDC |

| Motor rating | max. 200 W DC |

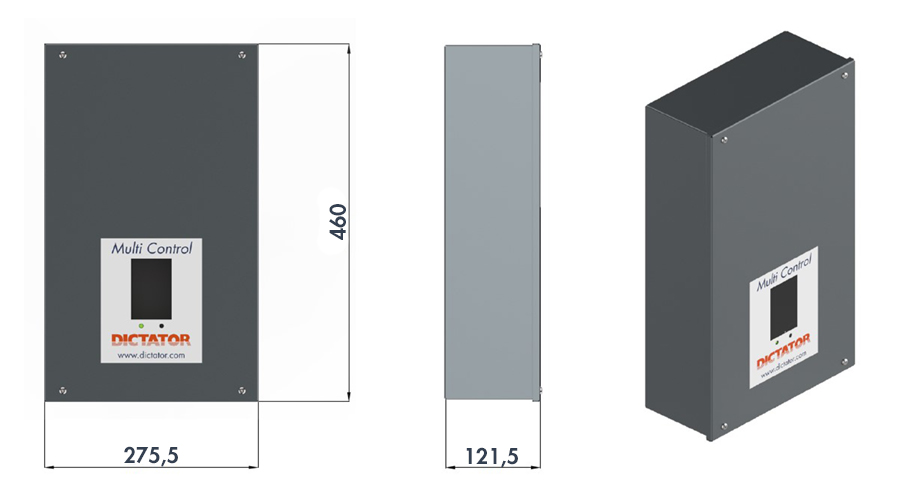

| Dimensions | H x W x D = 460 x 275,5 x 121,5 mm |

| IP rating | IP 40 |

| Recommended fuse protection | 5 A |

| Operating temperature | -25°C – +50°C (without power pack) |

Operating options / safety features

- Dead Man or Impulse Function for the keys OPEN and CLOSE (can be choosen separately for both directions, e.g. impulse OPEN, dead man CLOSE)

- Automatic Closing: As soon as the position OPEN has been reached the door closes automatically after a preset time (adjustable between 1 – 180 sec.)

- Alternating Impulse OPEN/CLOSE, alternating impulse OPEN/STOP/CLOSE or alternating impulse combined with automatic closing

- Partial Opening– 3 different positions: The door opens only partially (additional adjustable positions) ((separately adjustable hold-open-time for each position).

- STOP (different Stop behaviours in OPEN and / or CLOSE. STOP behaviour and deceleration ramps are adjustable direction-independently. Reversal of direction after STOP can be activated / deactivated, distance of direction reversal adjustable via time

- EMERGENCY STOP: Works like the safety equipment for the closing edge. Stopping distance according to EN 12453 possible.

- Safety equipment: According to the requirements of the EN 12453 safety devices with different functions / safety categories can be connected. In an adjustable range before the end positions, the safety elements can be deactivated

- If the safety element is defective, an error code is generated via the tested inputs and displayed directly on the control unit display.

Functions

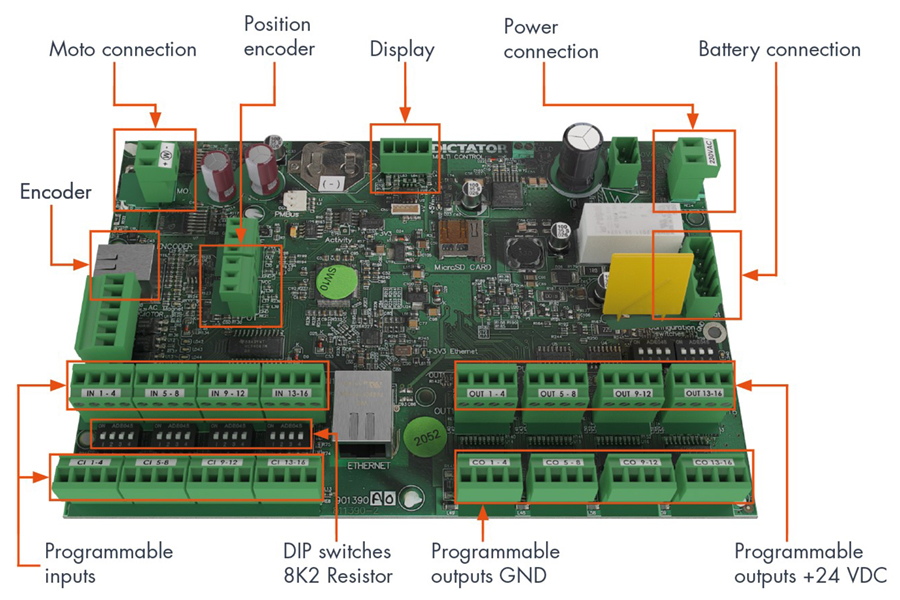

- Position control: The Multi Control is designed for a position control via encoder, integrated in the door operator. This permits a very precise positioning of the door (depending on the travel and the power transmission: max. 2 mm). However it is also possible to use separate position sensors or limit switches (4 pcs. required).

- Inputs: The Multi Control has a total of 16 tested floating inputs. They offer many configuration options, e.g. choice NO/NC. This enables the integration of a wide variety of switches like e.g. OPEN, STOP, CLOSE, alarm, limit switches.

- Outputs: The Multi Control has a total of 16 non-floating outputs for signalling and warning devices. They offer many configuration options, e.g. message to a building control panel, integration in conveyor systems, etc.

- Diagnostics: The display on the lid of the casing indicates error codes which help the customer service to analyze the problem. Additionally, the network connection of the control unit offers options for detailed diagnostics and remote maintenance without the need for an on-site appointment every time.

- Load recognition: Enables safety with DC drives through tolerance measurement of current consumption and speed by means of a STOP or STOP reversal of the door.

- Parameterisation: settings for the required door and gate movement, e.g. z.B. deceleration ramps, acceleration ramps, subsequent position changes, waiting times after a STOP, prewarning times, garage function.

Motor parameters

In order to achieve an optimum adjustment of the door drive to the door different motor parameters can be adjusted. Amongst them are e.g.:

- OPENING speed / CLOSING speed (separately adjustable)

- Creep Speed before reaching the positions OPEN and CLOSED (speed is reduced before reaching the final position, so that no separate final dampers are required, separately adjustable)

- Acceleration and Deceleration Ramps: Depending on the door weight and its movement

Installation

Installation notes

Installation notes

- The installation of the control system is very easy, as the electronics are fixed on a board that can be removed completely from the casing. The lid of the casing can also be taken off, as the flat cable connection to the display in the lid just has to be unplugged. The now very light casing can be fixed to the wall, without the danger of damaging the electronics by chance with e.g. a screw driver. The control system should be placed not farther than 30 m from the door operator.

- The control unit does not necessarily have to be accessible for setting, as it can be operated via wifi from a smartphone, tablet or notebook.

- Door operator, operating elements and safety equipments are connected to the removable binders. The blocks of binders are coded and therefore cannot be plugged into a wrong position.

Order information

Order Information

| Description | Part No. |

|---|---|

| Universal control system Multi Control, DC version, for DICTAMAT door operators | 740130 |

Downloads

| File name | Type |

|---|---|

| Documents | |

| Catalog: Universal control unit Multi Control | |

| Manual Multi Control |