Back checks

Prevent uncontrolled opening of hinged doors and windows

Characteristics

- Dampens doors/windows in the opening direction and limits the opening angle

- Various models cover a wide range of applications: from lightweight interior doors and windows to very large/heavy doors with high loads

- Many models can be used in combination with overhead door closers

- Installation accessories available for a wide range of situations

- Optionally with integrated hold-open in open position

- Material: steel, painted cylinder (standard: RAL 9006), many models are available in AISI 304, AISI 316

Product details

Standard series overview

All of the information below is intended as a general guide; other factors may need to be taken into account in individual cases. Please contact our customer service team to find the right back check for your application.

| Series | TB 10-23 | TB 14-28 | TBP 10-29 | TBR 14-35 |

|---|---|---|---|---|

| Series abbreviation | TB=Back checks with standard damping | TBP=Back checks with gradual damping | TBR=Back checks with adjustable damping | |

| Application area | For small / light doors | For medium and heavy doors with high (wind) load | For medium-sized and heavy doors with frequent operation or for doors with high requirements in terms of convenience | For extreme operating situations |

| Common applications | Interior doors | Industrial doors; exterior doors which are not operated frequently, e.g. side entrance doors | Frequently used doors, e.g. entrance doors to public buildings, schools; with high requirements in terms of convenience | Oversized doors and gates |

| Damping behavior Values may vary depending on installation situation and stroke length | Damping from approx. 40° opening angle | Damping from approx. 40° opening angle | Gradual / increasing final damping from approx. 55° opening angle | Damping from approx. 40° opening angle, with adjustable damping force |

| Options for damping adjustment | Start of damping can be delayed by reducing the oil filling quantity | Start of damping can be delayed by reducing the oil filling quantity | none | Damping force can be adapted |

| Can be combined with overhead door closers | No | Yes (stroke length 300/400 mm) | Yes (stroke length 300/400 mm) | No |

| Stroke length standard models | 250 mm | 250, 300, 400 mm | 250, 300, 400 mm | 300, 400 mm |

| The specifications for all other models can be found in the catalog pages. | ||||

Video

Technical data

| Material standard models | Piston rod hard chrome-plated; cylinder steel painted to RAL 9006 satin finish; fittings and installation accessories zinc-plated as standard |

| Cylinder paint options | The cylinder can be painted in other RAL colors upon request. There are some preferred colors that are available with relatively short lead times and at a lower surcharge: RAL 7040, 7016, 9005, 9007, 9016 (all satin matt). For more details, see section “Material”. |

| Stainless steel models | The back check series 10-23, 14-28 and 14-35 are available in AISI 304 and AISI 316 |

| Door weight | max. 200 kg; heavier doors upon request |

| Max. possible opening angle | 120°, depending on model and installation situation maybe lower |

| Optional function | Integrated hold-open in open position |

| We offer many custom solutions for different specifications. Just contact us. | |

Material

Installation accessories

You will find this information in the section “Installation“.

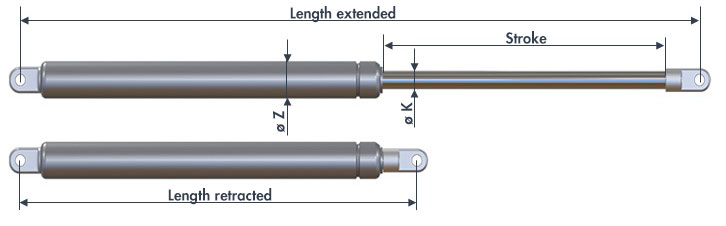

Dimensions

Here you will find the dimensions of the most frequently used back checks. The specifications for all other models can be found in the catalog pages.

Dimensions series TB 10-23

All dimensions in mm

| ø K | ø Z | Material | Hold-open | Stroke | Length retracted | Length extended | ø Eyelet |

|---|---|---|---|---|---|---|---|

| Stroke 250 mm | |||||||

| 10 | 23 | Painted steel | no | 250 | 350 | 600 | 8 |

| 10 | 23 | Painted steel | yes | 250 | 350 | 600 | 8 |

| 10 | 23 | Stainless steel | no | 250 | 350 | 600 | 8 |

| 10 | 23 | Stainless steel | yes | 250 | 360 | 610 | 8 |

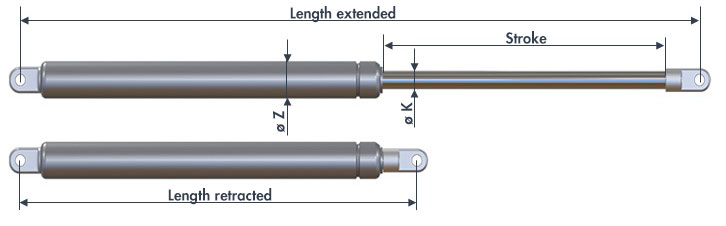

Dimensions series TB 14-28

All dimensions in mm

| ø K | ø Z | Material | Hold-open | Stroke | Length retracted | Length extended | ø eyelet |

|---|---|---|---|---|---|---|---|

| Stroke 250 mm | |||||||

| 14 | 28 | Painted steel | no | 250 | 350 | 600 | 8 |

| 14 | 28 | Painted steel | yes | 250 | 360 | 610 | 8 |

| 14 | 28 | Stainless steel | no | 250 | 350 | 600 | 8 |

| 14 | 28 | Stainless steel | yes | 250 | 360 | 610 | 8 |

| Stroke 300 mm | |||||||

| 14 | 28 | Painted steel | no | 300 | 450 | 750 | 8 |

| 14 | 28 | Painted steel | yes | 300 | 450 | 750 | 8 |

| 14 | 28 | Stainless steel | no | 300 | 450 | 750 | 8 |

| 14 | 28 | Stainless steel | yes | 300 | 450 | 750 | 8 |

| Stroke 400 mm | |||||||

| 14 | 28 | Painted steel | no | 300 | 600 | 1000 | 8 |

| 14 | 28 | Painted steel | yes | 300 | 600 | 1000 | 8 |

| 14 | 28 | Stainless steel | no | 300 | 600 | 1000 | 8 |

| 14 | 28 | Stainless steel | yes | 300 | 600 | 1000 | 8 |

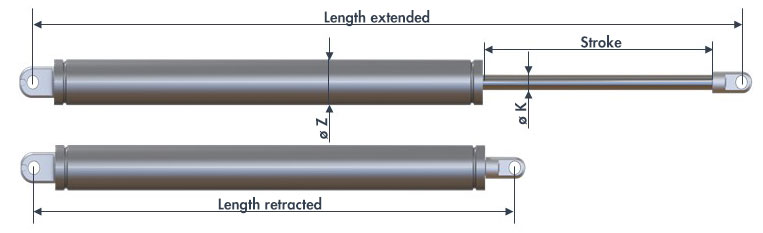

Dimensions series TBP 10-29

All dimensions in mm

| ø K | ø Z | Stroke | Length retracted | Length extended | ø Eyelet |

|---|---|---|---|---|---|

| Stroke 250 mm | |||||

| 10 | 29 | 250 | 360 | 610 | 8 |

| Stroke 300 mm | |||||

| 10 | 29 | 300 | 450 | 750 | 8 |

| Stroke 400 mm | |||||

| 10 | 29 | 400 | 600 | 1000 | 8 |

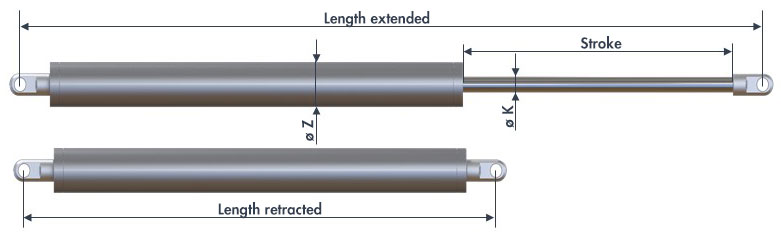

Dimensions series TBR 14-35

All dimensions in mm

| ø K | ø Z | Stroke | Length retracted | Length extended | ø Eyelet |

|---|---|---|---|---|---|

| Stroke 300 | |||||

| 14 | 35 | 300 | 450 | 750 | 8 |

| Stroke 400 | |||||

| 14 | 35 | 400 | 550 | 950 | 8 |

| 14 | 35 | 400 | 550 | 950 | 10 |

| Stroke 500 | |||||

| 14 | 35 | 500 | 650 | 1150 | 10 |

Dimensions installation accessories

In the catalog pages Installation accessories accessories you will find the data for all accessories.

On the page > Installation situations you will find the most common application situations including dimensions.

Installation

Installation accessories

When installing the back check, it is essential to ensure that it is firmly and securely fastened to the door and frame, as very high forces may occur.

Common installation situations

On the page > Installation situations you will find the most common application situations. DICTATOR offers a wide range of installation accessories for back checks for almost every application.

Catalog pages Installation accessories

In the catalog pages Installation accessories accessories you will find the data for all accessories.

Our service for you

To ensure that you receive the right product including accessories for your application, simply fill out our online questionnaire / print questionnaire (PDF) and send us pictures of the door/application. Based on your information, we will calculate the right solution for you, including installation accessories and fixing points. You will receive a product that fits your application perfectly and a door that functions as desired.

Installation instructions

We not only provide advice on product selection, we are also there for you if you have any questions regarding installation. Just contact us!

Application examples

Back checks are used, for instance, in situations where doors and windows can hit a wall or similar in an uncontrolled manner or be torn out of the user’s hand by wind, draft or even during normal opening. They ensure that hinged doors and windows do not slam open without control. They dampen excessive opening speed and limit the opening angle. This protects the door/window and the hardware. Thanks to a large number of installation accessories, many installation options are possible for almost any application.

> Find out more about the areas of application for back checks

Order information

Here you will find the ordering information for the most frequently used back checks. You can find the details for all other models in our catalog pages.

Order information series TB 10-23

| Description | Part no. |

|---|---|

| Back check 10-23-250-1/Öl-350-600-A-A, cylinder painted in RAL 9006 white aluminium | 302006-2 |

| Back check 10-23-250-1/Öl-350-600-A-A, with mechanical stop, cylinder painted RAL 9006 white aluminium | 302007-2 |

| Back check 10-23-250-1/Öl-350-600-A-A, AISI 304 stainless steel | 302010 |

| Back check 10-23-250-1/Öl-360-610-A-A, with mechanical stop, AISI 304 stainless steel | 302011 |

| Back check 10-23-250-1/Öl-350-600-A-A, AISI 316L / 316TI stainless steel | 302012 |

| Back check 10-23-250-1/Öl-360-610-A-A, with hold-open, AISI 316L / 316TI stainless steel | 302013 |

Order information series TB 14-28

| Description | Part no. |

|---|---|

| Stroke 250 mm | |

| Back check 14-28-250-1/Öl-350-600-A-A, cylinder painted in RAL 9006 white aluminium | 302020-2 |

| Back check 14-28-250-1/Öl-360-610-A-A, with mechanical stop, cylinder painted in RAL 9006 white aluminium | 302021-2 |

| Back check 14-28-250-1/Öl-350-600-A-A, AISI 304 stainless steel | 302022 |

| Back check 14-28-250-1/Öl-360-610-A-A, with hold-open, AISI 304 stainless steel | 302023 |

| Back check 14-28-250-1/Öl-350-600-A-A, AISI 316L / 316TI stainless steel | 302024 |

| Back check 14-28-250-1/Öl-360-610-A-A, with hold-open, AISI 316L / 316TI stainless steel | 302025 |

| Stroke 300 mm | |

| Back check 14-28-300-1/Öl-450-750-A-A, cylinder painted in RAL 9006 white aluminium | 302026-2 |

| Back check 14-28-300-1/Öl-450-750-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302027-2 |

| Back check 14-28-300-1/Öl-450-750-A-A, AISI 304 stainless steel | 302028 |

| Back check 14-28-300-1/Öl-450-750-A-A, with hold-open, AISI 304 stainless steel | 302029 |

| Back check 14-28-300-1/Öl-450-750-A-A, AISI 316L / 316TI stainless steel | 302030 |

| Back check 14-28-300-1/Öl-450-750-A-A, with hold-open, AISI 316L / 316TI stainless steel | 302031 |

| Stroke 400 mm | |

| Back check 14-28-400-1/Öl-600-1000-A-A, cylinder painted in RAL 9006 white aluminium | 302033-2 |

| Back check 14-28-400-1/Öl-600-1000-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302034-2 |

| Back check 14-28-400-1/Öl-600-1000-A-A, AISI 304 stainless steel | 302035 |

| Back check 14-28-400-1/Öl-600-1000-A-A, with hold-open, AISI 304 stainless steel | 302036 |

| Back check 14-28-400-1/Öl-600-1000-A-A, AISI 316L / 316TI stainless steel | 302037 |

| Back check 14-28-400-1/Öl-600-1000-A-A, with hold-open, AISI 316L / 316TI stainless steel | 302038 |

Order information series TBP 10-29

| Description | Part no. |

|---|---|

| Stroke 250 mm | |

| Back check progressive 10-29-250-1/Öl-360-610-A-A, cylinder painted in RAL 9006 white aluminium | 302102 |

| Back check progressive 10-29-250-1/Öl-360-610-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302103 |

| Stroke 300 mm | |

| Back check progressive 10-29-300-1/Öl-450-750-A-A, cylinder painted in RAL 9006 white aluminium | 302104 |

| Back check progressive 10-29-300-1/Öl-450-750-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302105 |

| Stroke 400 mm | |

| Back check progressive 10-29-400-1/Öl-600-1000-A-A, cylinder painted in RAL 9006 white aluminium | 302106 |

| Back check progressive 10-29-400-1/Öl-600-1000-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302107 |

Order information series TBR 14-35

| Description | Part no. |

|---|---|

| Stroke 300 mm, ø eyelet 8 mm | |

| Back check adjustable 14-35-300-1/Öl-450-750-A-A, cylinder painted in RAL 9006 white aluminium | 302217-2 |

| Back check adjustable 14-35-300-1/Öl-450-750-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302219-2 |

| Back check adjustable 14-35-300-1/Öl-450-750-A-A, AISI 304 stainless steel | 302220 |

| Back check adjustable 14-35-300-1/Öl-450-750-A-A, with hold-open, AISI 304 stainless steel | 302239 |

| Back check adjustable 14-35-300-1/Öl-450-750-A-A, AISI 316L / 316TI stainless steel | 302222 |

| Stroke 400 mm, ø eyelet 8 mm | |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, cylinder painted in RAL 9006 white aluminium | 302224-2 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium | 302226-2 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, AISI 304 stainless steel | 302230 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, AISI 316L / 316TI stainless steel | 302232 |

| Stroke 400 mm, ø eyelet 10 mm | |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, cylinder painted in RAL 9006 white aluminium, eyelet with 10 mm hole | 302225-2 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium, eyelet with 10 mm hole | 302227-2 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, AISI 304 stainless steel, eyelet with 10 mm hole | 302231 |

| Back check adjustable 14-35-400-1/Öl-550-950-A-A, AISI 316L / 316TI stainless steel, eyelet with 10 mm hole | 302233 |

| Stroke 500 mm, ø eyelet 10 mm | |

| Back check adjustable 14-35-500-1/Öl-650-1150-A-A, cylinder painted in RAL 9006 white aluminium, eyelet with 10 mm hole | 302234-2 |

| Back check adjustable 14-35-500-1/Öl-650-1150-A-A, with hold-open, cylinder painted in RAL 9006 white aluminium, eyelet with 10 mm hole | 302235-2 |

Order information installation accessories

| Model | Part no. | ||

|---|---|---|---|

| Zink-plated | AISI 304 | AISI 316 | |

| Mounting bracket | 205197 | 205249 | 205455 |

| Mounting bracket TB 70x45x36 mm, for mounting pin Ø 8 or 10 mm | 205489 | 205490 | 205491 |

| Mounting pin TB 25-14 mm, Ø 8 mm | 205511 | 205512 | 205513 |

| Mounting pin TB 45-14 mm, Ø 8 mm | 205514 | 205515 | 205516 |

| Mounting plate TB with 2 threaded holes M5 for mounting bracket 205197 | - | 205479 | - |

| Counter plate with threaded inserts for mounting bracket 205197 | - | 205468 | - |

| Mounting plate TB 220x46 mm | 205503 | 205504 | 205505 |

| Mounting flange TB Ø 42, pin Ø 8 mm | 205261 | 205281 | - |

| Mounting bracket TB 40x40x40 mm, pin Ø 8 mm | 205262 | 205282 | 205456 |

| Mounting bracket TB 50x40x20 mm, pin Ø 8 mm | 205263 | 205258 | - |

| Mounting bracket TB 180x70x53 mm, for mounting pin Ø 8 or 10 mm | 205462-W | ||

| Counter plate for mounting plate TB 45x220 mm, with threaded inserts | 205461 | ||

| Accessories specially for doors with overhead door closer | |||

| Mounting bracket TB-OTS 140 x 45 x 90 mm, for pin 8 or 10 mm | 205492 | ||

| Mounting bracket TB-OTS 250x106x90x84 mm, for pin Ø 8 or 10 mm, DIN left, mounted on non swing side | 205507 | ||

| Mounting bracket TB-OTS 250x106x90x84 mm, for pin Ø 8 or 10 mm, DIN right, mounted on non-swing side | 205508 | ||

| Mounting bracket TB-OTS 50x20x30 mm, pin Ø 8 mm | 205276 | ||

| Acessories back checks with Ø 10 mm eyelet (models of the TBR 14-35 series) | |||

| Mounting pin TB 25-16 mm, Ø 10 mm | 205517 | 205518 | 205519 |

| Mounting pin TB 45-16 mm, Ø 10 mm | 205520 | 205521 | 205522 |

| Mounting plate TB 45x220 mm, seat with pin Ø 10 mm | 205460 | ||

| Mounting flange TB 65x25 mm, pin Ø 10 mm | 205469 | ||

Downloads

Documents

| File name | Type |

|---|---|

| Catalog back checks | |

| Catalog: Installation accessories for back checks | |

| Online questionnaire | PDF questionnaire (print) | online/pdf |

| Brochure Back checks | |

| Installation Instructions Back checks |