Hold-open systems for hazardous areas

DICTATOR also offers hold-open systems especially for hazardous areas that meets the requirements of the ATEX directive 2014/34/EU. There is a general type approval (no. Z-6.500-2443) for the hold-open system.

Advantages

- Thanks to our large range of components and our many years of experience with demanding requirements in hazardous areas we can offer solutions for the widest range of demands

- We provide individual support of your projects and plan the components and their installation together with you – of course, also on site. This ensures your installation meets all safety and legal requirements

Types

- Hold-open system without door drive

- Hold-open system with door drive for operating the door

Details about the systems

Technical data

| Application area | hazardous zones 1 and 2 |

| Operating temperature | -20 °C to +40 °C |

| Igniton protection type fire detector | Ex II 1G Ex ia II C T5 (at max. 40 °C), only in combination with a safety barrier |

| Igniton protection type electromagnets Model with cable | Ex II 2G Ex mb IIC T6 Gb or Ex II 2D Ex mb IIIC T85°C Db |

| Ignition protection type electromagnets Model with terminal box | Ex II 2G Ex mb e IIC T6 Gb or Ex II 2D Ex mb e IIIC T85°C Db |

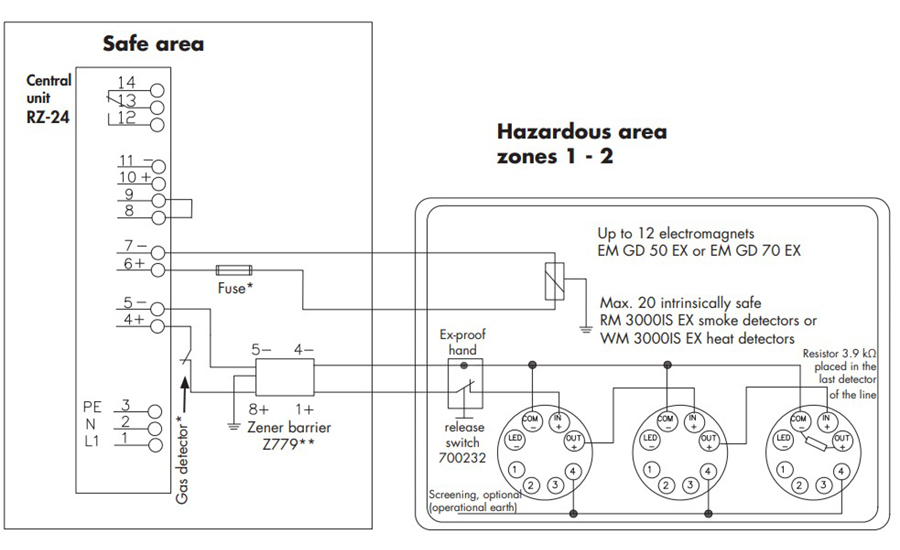

System without door operator

* Each ex-magnet has to be individually fused, with the fuse installed upstream of the magnet. You can find more information in the manual of the magnets. On site, the integration of a gas warning system must be checked by the ATEX representative on the basis of explosion protection guidelines.

** Please refer to the Zener barrier manual for the detailed connection diagram.

Fire doors that have to be kept open – e.g. because it is required for operation – require a hold-open system. The smallest unit of such a hold-open system consists of a fire detector, a power supply, an electromagnet and a hand release switch. In the event of fire or gas alarm the power supply to the electromagnet is interrupted, the door is released and automatically closed by a built-in spring, door closer or counterweight.

Whether an additional gas warning system is required must be checked by the EX representative of the operator.

The explosion-proof hold-open system is made up of maximum 20 smoke or heat detectors and up to 12 explosion-proof magnets. The explosion-proof magnet is available with two different holding forces. You also can choose between a version with integrated connection box or with an ex-proof connection cable.

The central unit RZ-24 and the safety barrier (Zener barrier) are installed outside the hazardous area. Special models with pressure capsulated casings for the hazardous area are also available on demand.

The cable recommended for the wiring within the hazardous area is an Ölflex cable 2 x 0.75 mm² (max. length 100 m).

Components:

- RZ-24 central unit with power supply

- Shunt safety barrier: Zener barrier Z779

- RM 3000IS EX smoke detector (or WM 3000IS EX heat detector) with base

- 3.9 kΩ resistor (included in the delivery of the RZ-24 central)

- Explosion-proof magnet

- Hand switch (part no. 700232)

- Gas warning system**: Whether a gas warning system (to be provided by the customer) is required must be checked by the EX representative on the basis of the explosion protection documents (requires a potential-free contact with a switching capacity of 24 VDC/100 mA).

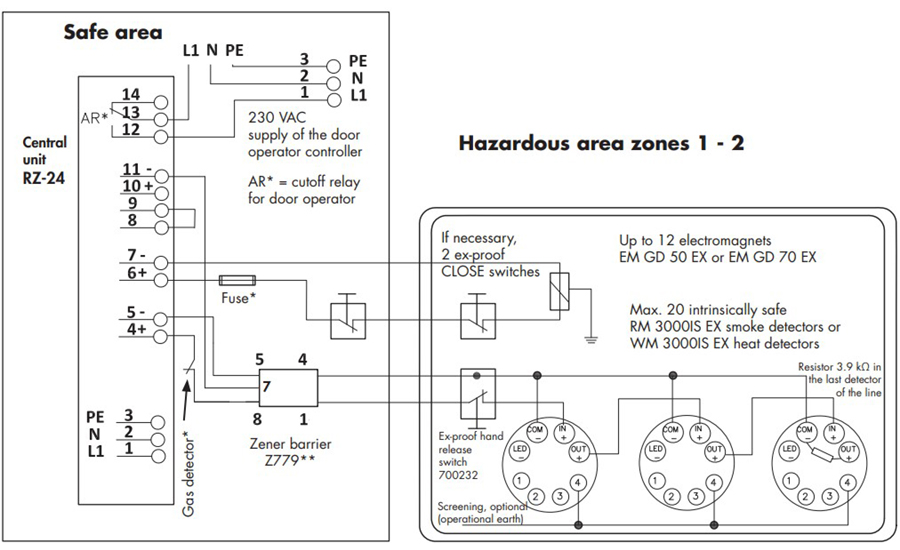

System with door operator

* Each ex-magnet has to be individually fused, with the fuse installed upstream of the magnet. You can find more information in the manual of the magnets. On site, the integration of a gas warning system must be checked by the ATEX representative on the basis of explosion protection guidelines.

** Please refer to the Zener barrier manual for the detailed connection diagram.

In order to open a fire door automatically, an approved, explosion-proof door drive can be used. In explosion-proof hold-open systems the magnets are generally installed only in the open position of the door and are not integrated in the door operator.

In the event of an alarm, it has absolutely to be made sure that the door closes and is not blocked due to an error of the control system. Therefore, in such a case, the relay integrated in the central unit RZ-24 automatically switches off the control system of the ex-proof door operator (see diagram).

The door operator used to open the fire protection door is not shown in the components list. Which door drive should be chosen depends on the type of door, the required forces, its functions, etc.

The central unit RZ-24 and the shunt safety barrier are installed outside the hazardous area. Special models with pressure capsulated casings for the hazardous area are available on demand.

The cable recommended for the wiring within the hazardous area is an Ölflex cable 2 x 0.75 mm², max. length 100 m.

Components:

- RZ-24 central unit with power supply

- Shunt safety barrier: Zener barrier Z779

- RM 3000IS EX smoke detector (or WM 3000IS EX heat detector) with base

- 3.9 kΩ resistor (included in the delivery of the RZ-24 central)

- Explosion-proof magnet

- Hand release switch (part no. 700232)

- Gas warning system**: Whether a gas warning system (to be provided by the customer) is required must be checked by the EX representative on the basis of the explosion protection documents (requires a potential-free contact with a switching capacity of 24 VDC/100 mA).

- If necessary, ex-proof CLOSE switches for the door

Downloads

| File Name | Type |

|---|---|

| Documents | |

| Catalog: Explosion-proof hold-open systems | |

| Technical manual RZ-24 | |

| DWG Drawings | |

| DWG Central Unit RZ-24, 040553 | dwg |