Push type gas springs

Function & application areas

DICTATOR quality gas springs lift your heavy weights – always effortlessly, gently, and without a hitch. This helps protect people and goods. Thanks to their wide range of possible options, they can be used in all types of structures where components need to be lifted and/or held open or where the weight needs to be counterbalanced.

Product range

The application possibilities are as diverse as our model ranges. That is why DICTATOR does not have fix type tables and only a few stock types. We manufacture your gas spring for your application, according to your requirements – even as a single unit or in small quantities.

In addition to high quality, DICTATOR gas springs also offer numerous possible additional fittings, such as valve, oil chamber, protective tube, impression spring or bio-oil – which substantially expands the scope of application.

Product details

Push type gas springs range overview

| Ø Piston rod Ø Cylinder | 3 10 | 4 12 | 6 15 | 8 19 | 10 23 | 14 28 | 20 40 | 25 55 | 30 65 |

|---|---|---|---|---|---|---|---|---|---|

| Min. stroke (mm) Max. stroke (mm) | 10 80 | 10 200 | 20 300 | 40 500 | 40 700 | 50 700 | 50 600 | 100 500** | 100 350** |

| Damping | 0,1 | 0,1 | 0,1,2,3 | 0,1,2,3 | 0,1,2,3 | 0,1,2,3 | 0,1,2,3 | 1 | 1 |

| Min. force Max. force | 10/15 N 100 N | 10 N 180 N | 40 N 400 N | 80 N 700 N | 100 N 1200 N | 150 N 2500 N | 300 N 5000 N | 500 N 7500 N | 750 N 10000 N |

| Comp. L (GZ-GZ) * | ext L - S | ||||||||

| Ext. L (GZ-GZ) * | 2x S + 32 | 2x S + 32 | 2x S + 28 | 2x S + 43 | 2x S + 43 | 2x S + 46 | 2x S + 100 | 2x S + 140 | 2x S + 160 |

| End fittings | GZ, A, G WG | GZ, A, G WG | GZ, A, G WG, KGA, GK | GZ, A, G WG, KGA, GK | GZ, A, G WG, KGA, GK | GZ, A, G WG, KGA, GK | GZ, A, G WG, KGA, GK | GZ, G - | GZ, G - |

| Oil chamber (4) * | n/a | n/a | L + 15 | L + 15 | L + 15 | L + 15 | L + 15 | n/a | n/a |

| Valve (5) | option | option | option | option | option | option | option | standard | standard |

| Protective tube (6) * | n/a | L + 5 | L + 5 | L + 5 | L + 5 | L + 5 | L + 5 | L + 5 | L + 5 |

| Helical spring (7) * | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a |

| Ø Protective tube | - | 15 | 19 | 23 | 28 | 32 | 45 | 60 | 70 |

| Dimension PDF | |||||||||

* All dimensions (length) in mm [e.g.: 8-19 range; stroke 50; extended L = 2 x 50 + 43 = 143 mm] ** Max. stroke length limit due to the regulations of the Pressure Equipment Directive

* Types of damping

0= without damping

1= damping on extending stroke

2= damping on compression stroke

3= damping on both extending and compression stroke

Oil chamber

- Nearly all DICTATOR gas springs are available with an additional oil chamber.

- It prevents the seal on the piston rod from drying out and failing. The oil also reduces friction and ensures easy sliding of the piston rod.

- Always necessary when the gas spring is installed horizontally or when its normal position deviates by more than 30° from the vertical position.

- Not necessary for gas springs installed with the piston rod pointing downwards, since the oil quantity in the cylinder is always in direct contact with the seal anyway.

Please be aware that gas springs with an oil chamber need a slightly longer cylinder.

Valve

- The valve allows you to decrease gas preassure and reduce the extending force yourself.

- Order your gas springs with a valve if you are not sure about the exact force required or if you want to use the same type of gas spring to balance different weights, e.g. on different windows.

- Gas springs with a valve are also ideal for determining the required force on a sample application. Then you can send us the gas spring set to the correct preassure and we will measure it and manufacture them specifically for you without having to include a valve on each gas spring.

Protective tube

- For applications in places in which there is a lot of dirt (e.g. on road sweeping machines or in sandblasting cabins)

- They protect the piston rods from mechanical damage and thus generally extend the operational life of all gas springs, as scratches, dust, dirt, paint, etc. can damage the surface of the piston rod and this lead to premature failure of the gas springs.

Gas springs with protective tube are 5 mm longer.

Helical spring

- Diese Spiralfedern überwinden zuverlässig die Anfangsreibung, auch nach langen Pausen, in denen die Gasfedern nicht bewegt wurden.

- We recommend ordering gas springs with an additional helical spring if you want the flap / hatch to open on its own after releasing it.

- Normally used in hatches that should open automatically after unlocking, emergency exit windows and smoke ventilation.

- The helical spring can be installed inside the gas spring cylinder or on the piston rod.

Please use our advisory service to help select the most suitable product for your application.

Bio-oil

- Environmentally friendly bio-oil, with rape seed oil base, enables the installation of gas springs with damping in areas where the use of mineral oil or silicone-based synthetic oil is not permitted (e.g. in the food or pharma industry or in machines and factories which produce chemicals or paint).

- DICTATOR gas springs and dampers with bio-oil have undergone extensive testing even in very high and very low temperatures.

- They can be used in a temperature range from +60° C (+140° F) to approx. -20° C (-4° F).

- If required, the gas springs can also be furnished with FDA conform oil (additionally indicated with code number 8).

CAD configurator gas springs

Gasdruckfeder Anschlüsse

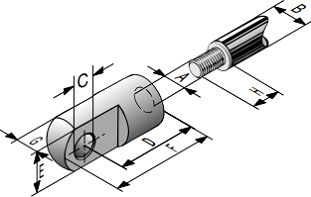

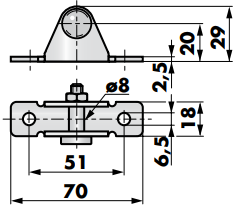

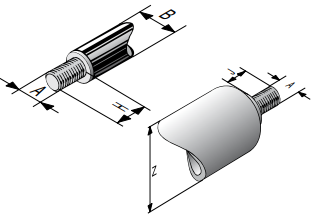

| 1) Threaded end (GZ) | 3-10 | 4-12 | 6-15 | 8-19 | 10-23 | 14-28 | 20-40 | 25-55 | 30-65 | |

|---|---|---|---|---|---|---|---|---|---|---|

| A | M3,5 | M3,5 | M5 | M8 | M8 | M10 | M14x1,5 | M20x1,5 | M24x2 |

| B | Ø3 | Ø4 | Ø6 | Ø8 | Ø10 | Ø14 | Ø20 | Ø25 | Ø30 | |

| H | 5 | 5 | 6,5 | 10 | 10 | 10 | 15 | 30 | 40 | |

| J | 5 | 5 | 8 | 12 | 12 | 12 | 15 | 30 | 40 | |

| Z | Ø10 | Ø12 | Ø15 | Ø19 | Ø23 | Ø28 | Ø40 | Ø55 | Ø65 |

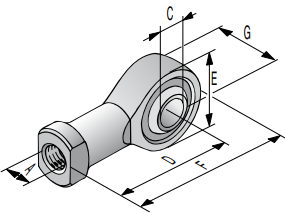

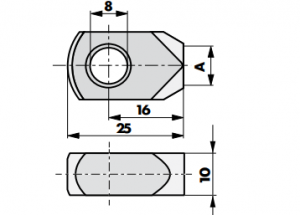

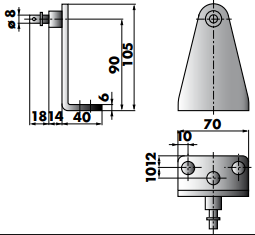

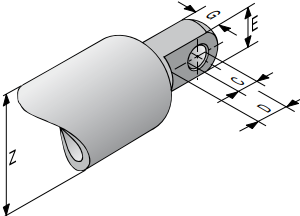

| 3) Eyelet on cylinder (A) - pressed into cylinder | 3-10 | 4-12 | 6-15 | 8-19 | 10-23 | 14-28 | 20-40 | |

|---|---|---|---|---|---|---|---|---|

| C | Ø4 | Ø4 | Ø6 | Ø8 | Ø8 | Ø8 | Ø14 |

| D | 7 | 7 | 9 | 11 | 13 | 16 | 20 | |

| E | 8 | 8 | 10 | 14 | 18 | 20 | 32 | |

| G | 4 | 4 | 6 | 10 | 10 | 10 | 14 | |

| Z | Ø10 | Ø12 | Ø15 | Ø19 | Ø23 | Ø28 | Ø40 |

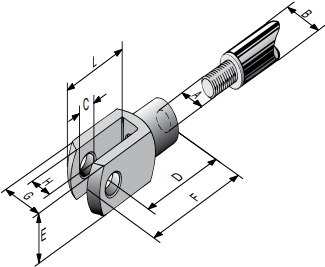

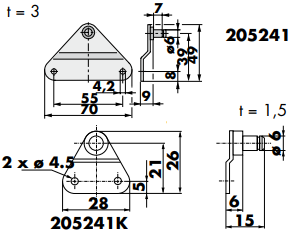

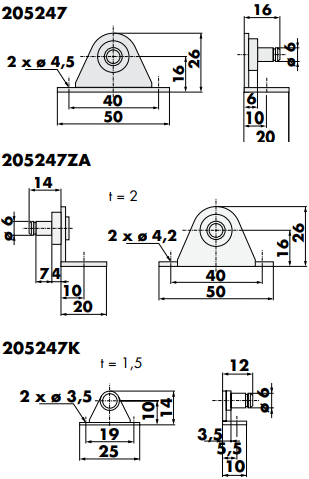

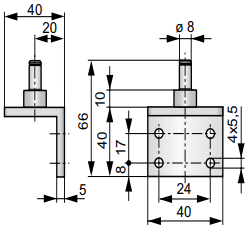

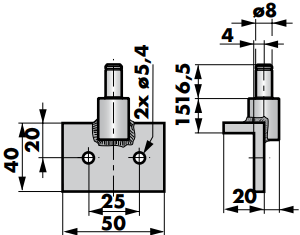

| 6) ES-pin for fixing fork | 3-10 | 4-12 | 6-15 | 8-19 | 10-23 | 14-28 | 20-40 | |

|---|---|---|---|---|---|---|---|---|

| C | Ø4 | Ø4 | Ø5 | Ø8 | Ø8 | Ø10 | Ø14 |

| D | 11 | 11 | 14 | 22 | 22 | 28 | 38 | |

| G | 9,5 | 9,5 | 12 | 19 | 19 | 23 | 31 |

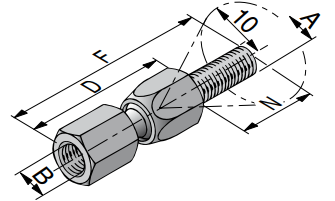

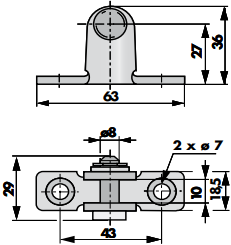

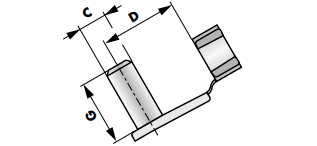

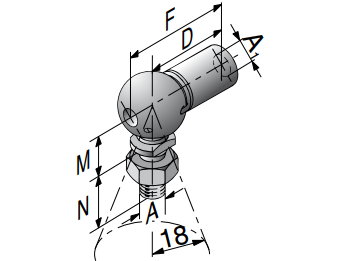

| 7) Ball & socket joint (WG) for piston rod and cylinder | 3-10 | 4-12 | 6-15 | 8-19 | 10-23 | 14-28 | 20-40 | |

|---|---|---|---|---|---|---|---|---|

| A1/A | M3,5/M4 | M3,5/M4 | M5 | M8 | M8 | M10 | M14x1,5 |

| D | 18 | 18 | 22 | 30 | 30 | 35 | 45 | |

| F | 24 | 24 | 28 | 39 | 39 | 46 | 60 | |

| M | 9 | 9 | 9 | 13 | 13 | 16 | 20 | |

| N | 10,3 | 10,3 | 10 | 16 | 16 | 19 | 28 |