HAUG Antriebssysteme GmbH

History | About us | Our strengths | Quality | Products

History

The company HAUG Antriebssysteme was founded in 1983. In the middle of the Swabian Alb, in Hermannsdorf, a town of just about 30 inhabitants, the DICTATOR idea factory was created – initially in a former cowshed – for all products associated with operator technology.

The first product – a groundbreaking innovation at the time – was semi-automatic operators for sliding fire doors, followed in 1984 by fire locking systems for data protection safes as a custom development. Fully automated drives for fire doors followed, and later drives for all types of doors and gates. A particular focus has always been the implementation of customer-specific automation solutions, e.g. the automation of a 93 m long telescopic sliding gate in 1998.

The Swabian inventive spirit did not stop there, however, but also provided – and still provides – groundbreaking developments in other areas. As early as 1987, HAUG developed and then produced dampers for toilet lids. Plastic made its debut as a material in the damping sector. In 2008, the incredibly flexible lamellar radial dampers – despite the plastic injection-molded housing – were developed on this basis, which were also patented in 2011.

The constant innovations and further developments went hand in hand with visionary production technology. As early as 1986, AutoCAD was an integral part of the design activity. For the production of up to 100,000 toilet lid dampers per year, a largely automatic production line was developed and also built in-house. In 1998, the first CNC machines were used for small series production, although for many years the widespread opinion prevailed that CNC systems were only useful for large series. The same applied to the use of 2D and 3D drawing programs.

Since so many ideas and new products needed more and more space, the first hall was added in 1988. In 1998, another annex was built to expand this hall. However, this was not sufficient for long either. Since further construction at the existing location was not possible, a first hall was rented in nearby Bitz in 2001, and in 2005 additional production rooms were added for the production of the entire damper program.

However, all these measures were not enough to provide sufficient space for the successful development of the company. The only forward-looking solution was the construction of a spacious new building with sufficient additional space for further expansion. In July 2014, all locations were then united under the roof of the new, modern company building in Bitz.

HAUG Antriebssysteme today

About us

We rise to every challenge, enthusiastically solving special requirements in the operator and damping industries. Although we do not have a sales department on site, we still work hand in hand with our customers, as this is the only way to implement truly fitting solutions – and this is a new incentive for us every time. Our products can be found all over the world, such as a special automation solution in the Hermès skyscraper in Tokyo – and we are enormously proud of this!

The continuous development of new products and of special solutions, the constant further development of our existing products, the greatest possible automation of small series and, of course, the manufacture of our products to the highest quality standards, we manage all this with just under 10 people. It simply works because we are a well-coordinated team in which everyone has a wide range of responsibilities, which makes our work all the more interesting.

And the whole thing is so much fun for us, not least because we work in an extremely customer-oriented way. For us, a production order is not just a number. We know each customer and the application in detail, and we enjoy “keeping an eye” on our products even after they have been finished, right up to the point where they are installed (e.g. the DICTAMAT 50 sliding door closers, which were installed in luxury cabins on a cruise ship). We all are able and willing to contribute with our ideas, we like to take on responsibility, and our families are almost part of the business.

Our strengths

The more complicated the requirement, the greater the ambition to find a suitable solution. The knowledge and experience gained from over 30 years of development work is invaluable.

As an example, only this way it is possible to develop the new lamellar radial damper, which was even patented due to its revolutionary technology – although beforehand, even with more intensive work on the subject, there was hardly any chance of a groundbreaking new design in this area.

Just as important as the ideas for new products, however, is to focus on cost-effective production as early as the development phase. This is where the practical man in Swabia comes into his own.

We have always attached great importance to always using the latest technology and even developing complete production lines ourselves, which enable rational production and also ensure consistent, high quality with short lead times. Largely automatic production lines also for the toilet lid dampers and radial dampers prove our inventive spirit also in this area.

Our very different product areas – door and gate operators with control units and the associated spring rope pulleys on the one hand, and hydraulic dampers on the other – also constantly ensure the necessary openness to all technical innovations.

A very important point for us, however, is also the extremely close cooperation with the sales department at home and abroad, with the technical customer support at DICTATOR and, of course, with the end customers. For this reason, a spacious conference and meeting area could not be missing in the new company headquarters.

Quality

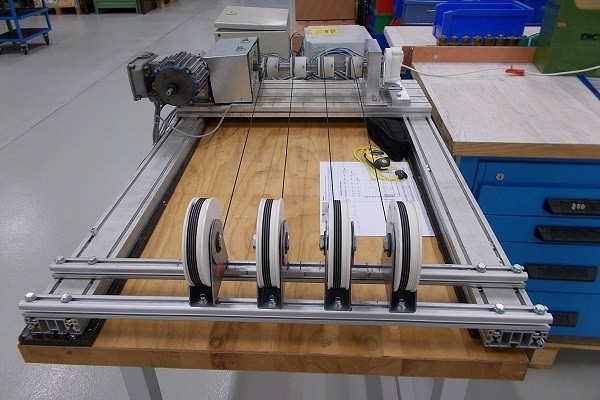

A very important place in the new production building is occupied by our testing and inspection department, where we carry out tests during the development of new product solutions as well as subject our series products to constant endurance and load tests.

All operator solutions and closing devices are put through their paces on a 10 m long test stand for all applications involving sliding doors and gates, on which we can simulate door weights between 200 kg and 2000 kg. This includes endurance tests, function checks and verification of the effects of possible improvements or modifications.

Before leaving our premises, all door and gate operators are individually configured together with the control unit and checked again for correct functioning.

For the spring pulleys we also have several endurance test devices, depending on the force of the spring pulley and the respective working travel.

Of course, we also have the necessary test devices to ensure the function of our products under very high or very low temperatures.

However, all of this is only part of the quality assurance process at our company. Very important are the quality controls built into the production processes. And, of course, the fact that we all identify 100% with our products. We have our customers as well as the respective applications “in front of our eyes”, so to speak, during production and therefore feel personally responsible for ensuring that everything works perfectly.

Products

The product range of HAUG Antriebssysteme at a glance:

- Door and gate operators

- Fire door operators

- Semi-automatic fire door operators

- Spring rope pulleys

- Sliding door closers

- Radial dampers, including the patented LD series

- Toilet seat dampers

- Closing systems for data protection strong rooms

- … and many special solutions