DICTATOR Technik Berlin

History | Production in Bernau | About us | Our strengths | Quality | Products

History

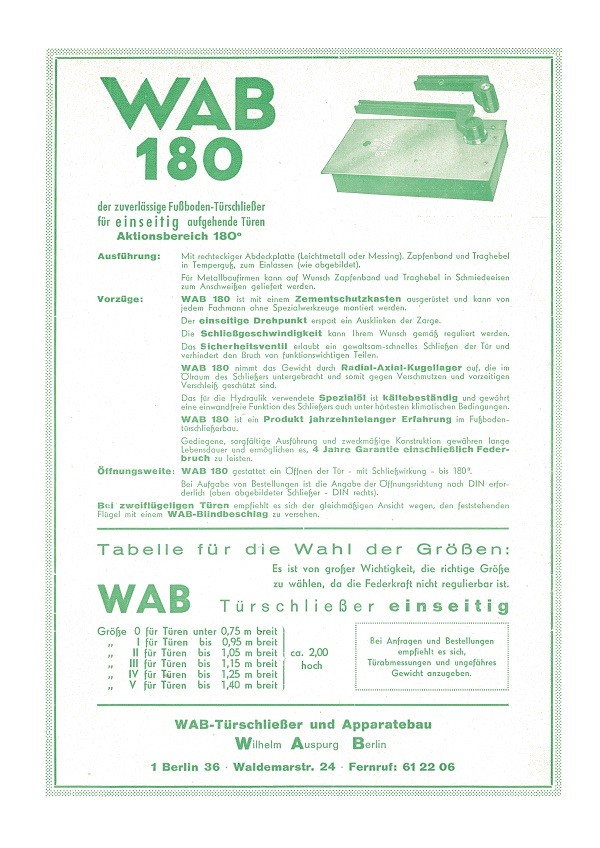

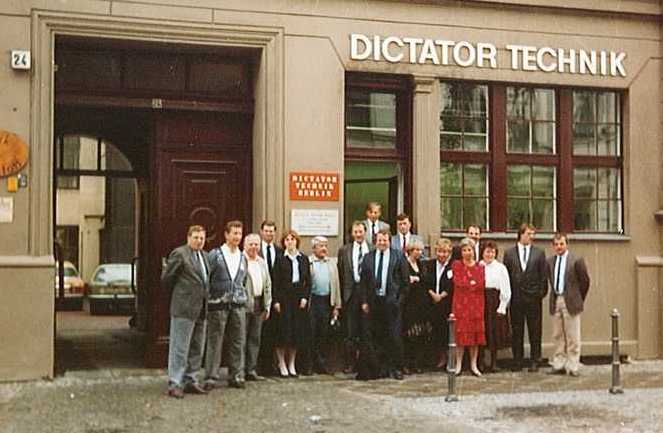

DICTATOR Berlin was founded in 1982 by taking over the company WAB (Wilhelm Auspurg Berlin), a long-established Berlin company. Since about 1930, the company manufactured extremely heavy-duty floor springs, the WAB 90, WAB 135 and WAB 180 (patented with No. 1063.931) in Berlin-Kreuzberg in backyard rooms typical of the area. Later, the WAB 76 and WAB 40/57 door sequence selectors were added, as well as the door buffers.

A business relationship between DICTATOR and WAB already existed since 1971. At that time, DICTATOR included the floor spring WAB 180 in its product range. In 1976 WAB took over the DICTATOR sales office for West Berlin, which at that time was still an “enclave” in the former GDR.

After the takeover of WAB by DICTATOR Berlin, the company gradually expanded. Another floor in the rear building of Waldemarstraße 24 was rented and the first floor of the front building now served as office and warehouse.

After the fall of the Berlin Wall, the sales area of the DICTATOR Berlin sales office spread to the whole of Berlin as well as the new states of Mecklenburg-Western Pomerania, Brandenburg and Saxony-Anhalt. In 2007 Saxony and Thuringia were also added.

In 1996, the company moved to its very own premises, a spacious new building in Basdorf near Wandlitz, north of Berlin.

The successful marketing and the constant expansion of the product range as well as the relocation of the DICTATOR gas spring production to DICTATOR Berlin led to the addition of a second, much larger production hall as early as 2002/2003.

DICTATOR Berlin today

Our production in Bernau

The new building in Basdorf, which seemed “spacious” to us in 1996, became too small again a little over 10 years later, despite the addition of another, much larger building in 2003. It was time to set the next milestone in the history of DICTATOR Technik Berlin: In 2016, we were able to acquire a future-oriented property with 15,000 sqm in the newly developed industrial park “Schönow Pappelallee” of the city of Bernau.

This year we started building the – at least from today’s point of view 🙂 – more than generous production hall with a floor space of 4200 m². The front building is a two-storey office building which will also include modern staff rooms. The complete move to the new location is planned for the second half of the year 2019.

Finally, at the end of 2019, we moved to the new location with the more than generous production hall with 4,200 sqm of floor space (just to estimate the scale: our old property in Basdorf would fit completely inside the new production hall). The head of the building is a two-story office building, which also houses a large conference room and modern recreation rooms for our employees.

Of course, a photovoltaic system on the roof could not be missing in the new building, because we at DICTATOR Berlin see ourselves as committed to the environment. This also includes good thermal insulation of the building, a modern heating system, plenty of natural light in the production halls and investment in state-of-the-art, high-quality lighting systems.

The move to the new building was also accompanied by a change in the finish of many of our products. Since we manufacture our gas springs and oil dampers on a customer-specific basis, there was at least one transport of cylinder tubes to the galvanizing plant and back to us every week. In addition, the number of galvanizing plants meeting our quality standards kept getting smaller and smaller. As a consequence, we invested in a modern paint shop in our building. This eliminates unnecessary shipments, delivery times are shorter because painting with drying time takes much less time than off-site galvanizing, and we can now offer our customers an additional service: gas springs, oil dampers and back checks are now also available in RAL colors according to customer requirements.

Another major investment helps us in the present times of severe supply problems: a motor-driven cantilever racking system with a footprint of 24 m x 11 m is now available in the new building. With this system, we have created storage capacities with foresight that enable us to stock annual requirements in terms of tubes and piston rods. This is because we require special, high-quality designs, some of which are manufactured especially for us.

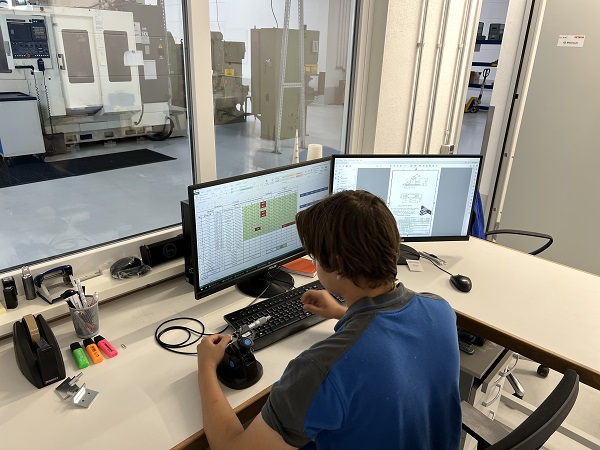

The machine park of CNC lathes and milling machines has been further expanded in the new building and supplemented by additional special machines. In the assembly area, it was possible to set up separate assembly stations for each product, which made it possible to further optimize the final assembly of the products.

The conditions at the new location put us in a position to continue expanding in the future. Our production and product range is constantly being expanded, and innovative technologies are finding their way in. In addition, we are offering our customers an ever more comprehensive and faster service. There is enough space in the production hall for new, state-of-the-art machines and equipment – and of course we are constantly expanding our staff at the same time!

At the end of 2019, the time has finally come: The new building is ready to move-in

Thanks to the new painting facility, delivery times can be kept short, gas springs, oil dampers and back checks can be supplied in additional colors and unnecessary transportation can be avoided.

The new movable cantilever rack provides space for large supplies of raw material, thus ensuring delivery capability.

About us

In the meantime, almost 30 employees as well as several apprentices ensure that our many different products, of which more than one third is made to order, can be manufactured with the highest quality and short delivery times. In addition, the professional, competent, individual technical support of all customers in the sales territory plays a very important role.

And there is something else that is of crucial importance to us: the joy of working together, the personal interaction, the enthusiasm for proceeding hand in hand with our customers and thus constantly being able to offer new solutions. This family atmosphere ensures that, for us, work is a positive part of daily life!

Our strengths

A decisive contribution to our success has been the fact that we are not exclusively a manufacturing company, but also have constant direct contact with customers thanks to our sales activities. Many of our products, which today make up a significant part of our production, were developed together with our customers based on their requirements. One of these products is the gate closer DIREKT, which is almost essential for fencing systems today. It safely and reliably ensures closed gates, with adjustable closing speed (see references). Another example is our back checks, which prevents doors from slamming open in an uncontrolled manner.

For us, the most important thing is the optimal automation of our manufacturing processes in areas where it makes sense to do so, and where this will lead to a better quality not only of the product, but of the entire service.

An even more important role, however, is played by the personal commitment of our employees, their cooperation, their flexibility, their competence and also their enthusiasm for their work and our products. Only this way can we produce and dispatch e.g. gas springs in urgent cases on the same day in customer-specific executions. This also enables us to develop special solutions for often quite tricky requirements – which we can then also manufacture quickly and inexpensively even in spite of small quantities.

Quality

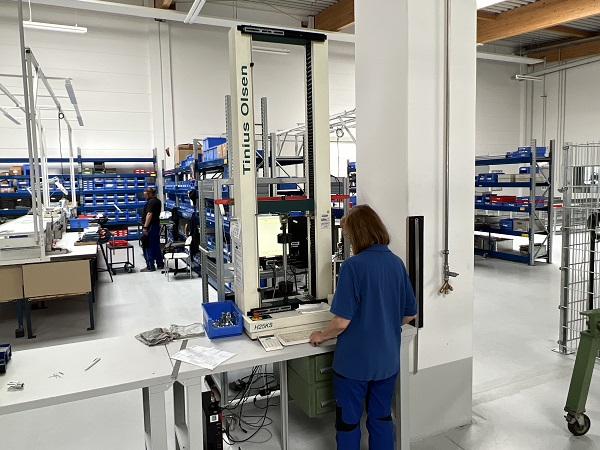

The high quality standard as well as the flexibility of our production is ensured by a balanced mix of state-of-the-art machines and conventional turning and milling machines, by sophisticated assembly processes and, above all, by our motivated staff.

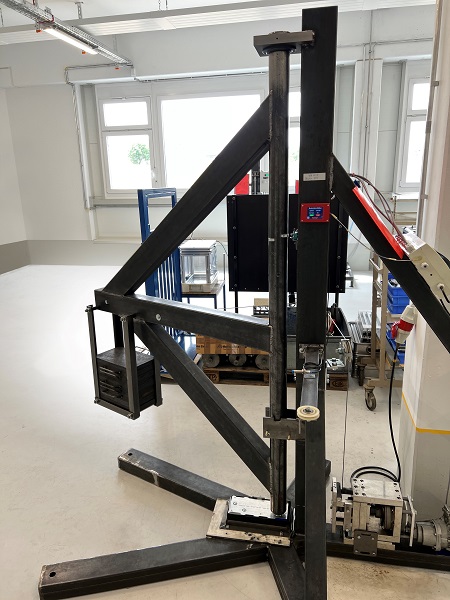

Very special attention is paid to quality assurance. This includes constant quality control during ongoing production, testing of modifications or variants, exact determination of the performance of our products, as well as endurance tests, limit tests and much more.

We are particularly proud of our two testing and measuring facilities in the area of gas spring and oil damper production. After filling, the exact force curve of each DICTATOR gas spring is measured on our “Hounsfield” and compared with the correct characteristic curve. Subsequently, each measurement is stored, assigned to the respective gas spring type and the corresponding production batch.

For the DICTATOR oil dampers, a testing system specially developed according to our specifications is available. It enables both the exact measurement of the damping characteristics of the finished product and – already in the development phase – the analysis of the effects caused by the use of different oils, nozzle bores, seals as well as many other parameters. This enables us at DICTATOR Berlin to offer customer-specific damping solutions that really do meet the exact requirements of the customer.